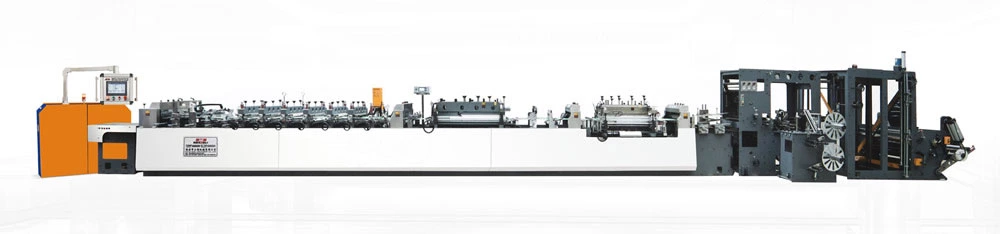

High Speed Pillow Center Sealing Bag Making Machine

- Voltage

- 380V

- Max film width

- 1250mm

- Suitable material

- BOPP, COPP, PET, PVC, nylon and other plastic composite films, multi-layer co-extruded films, aluminized composite films, paper-plastic composite films, pure aluminum foil composite films

- Speed

- 60-180pcs/min

High Speed Pillow Center Sealing Bag Making Machine

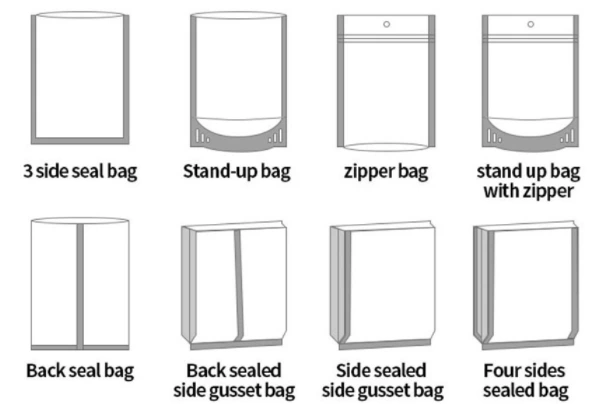

The bag styles that can be produced

Introduction

The machine is well-processed and assembled, with beautiful appearance and reasonable structure. The whole machine runs smoothly and has low noise. It adopts PLC double servo traction control, so that the unwinding and overhead materials are continuously drawn forward by the third traction motor at a constant speed. Centralized control of temperature by computer reduces power consumption. The intermediate tension floating roller adopts the dynamic compensation mode, which makes the up and down fluctuation very small during the drawing process and the intermediate tension control is stable.

the multifunctional Laminated Bag Making Machine by servo motors. It is widely used in producing 3 Side Sealing Bag, Zipper Pouch(3 Side Sealing Bag with zipper), Doypack(3 Side Sealing Stand-up Zipper Pouch Bag), 4 Side Sealing Bag for different plastic packaging.

Machine Advantage

Main electrical configuration:

Traction dual servo motors, equipped with Panasonic PLC, AC motor driven by the main drive inverter, temperature control 16 channels, unwinding constant tension

Suitable base material:

BOPP, COPP, PET, PVC, nylon and other plastic composite films, multi-layer co-extruded films, aluminized composite films, paper-plastic composite films, pure aluminum foil composite films

Number of heat sealing knives:

Vertical sealing adopts 4 sets of upper and lower heating and upper and lower cooling,Horizontal sealing adopts 3 sets of upper and lower heating and 2 sets of upper and lower cooling

Wallboard thickness:

10mm (produced by Shanghai Baosteel)

Color: brown body, white rust steel cover, black parts, nickel-plated, chrome-plated

Control system model:

Japan Panasonic PLC composite film high-speed bag making machine control system

Technical Parameters

|

Material |

All kinds of laminated hot-seal fim and peper |

|

Maximum mechanical beat |

180 beats/min(Actural speed depends on material and bag type) |

|

Maximum unwinding line speed: |

≤40m/min (depending on the material) |

|

Bag length size: |

600mm |

|

Maximum width: |

50-400 mm double delivery is used for length exceeding this length (maximum 6 times delivery) |

|

Maximum size of the roll: |

Φ 900×1250 mm (diameter×width) |

|

Positioning accuracy: |

≤±0.5mm |